D&S Resources successfully fabricated a 130,000L self-bunded tank for storing 98% sulfuric acid. Built to Australian standards, it ensures maximum safety with secondary containment and pressure testing. A reliable, custom-built solution for hazardous material storage.

D&S Resources successfully completed the fabrication and construction of a 130,000L self-bunded tank designed for storing 98% sulfuric acid. This custom-built tank was engineered to meet Australian standards, ensuring safe containment of hazardous materials.

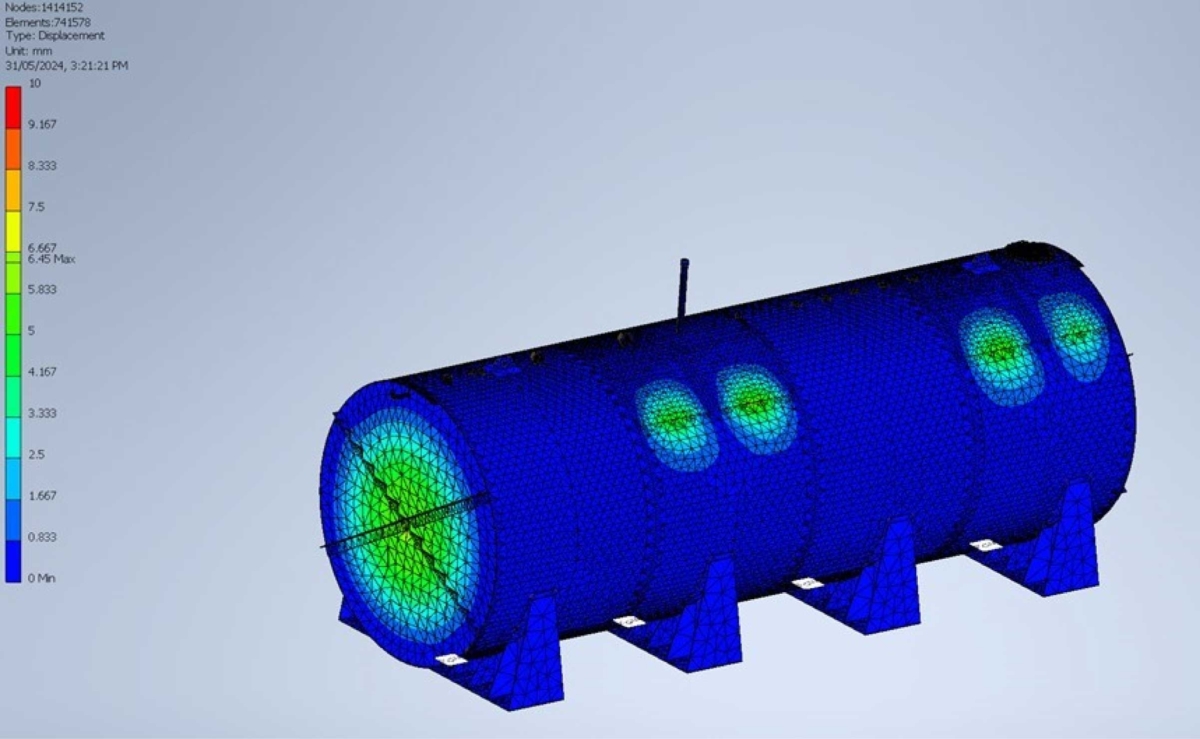

Key aspects of the engineering and fabrication included:

- General Arrangement Drawings

- Detailed Fabrication Drawings

- Finite Element Analysis

- Ground Bearing Pressure Analysis

- Lifting Lug Engineering and Basic Lift Plan

The tank featured secondary containment to provide an additional safety layer in the event of a failure. The fabrication process included:

- Fabrication and assembly of the tank

- Holding brackets mounted on top of the tank for cable tray installation

- Earthing lugs and lifting lugs

- Fabrication and assembly of an access ladder and platform

- External tank finish in white

- Galvanization of the access ladder and platform, painted yellow

- Pressure testing of the vessel

For safe and reliable storage solutions, contact D&S Resources to discuss how we can help with your next project.